Lean production: reliable processes, short process times

Using the combination of modular systems and multifunctional equipment results in manufacturing processes, which fulfil all costumer requirements. Lean production – high quality products, short process times. If you need further information on our capabilities, please send an inquiry by mail to sales@laborchemie.de

From lab scale to production in small ton scale: we offer possibilities for all amounts.

Our experience. Your order: Multifunctional equipment for highest demands, purity and scalability in cGMP- and non-GMP-areas.

Equipment

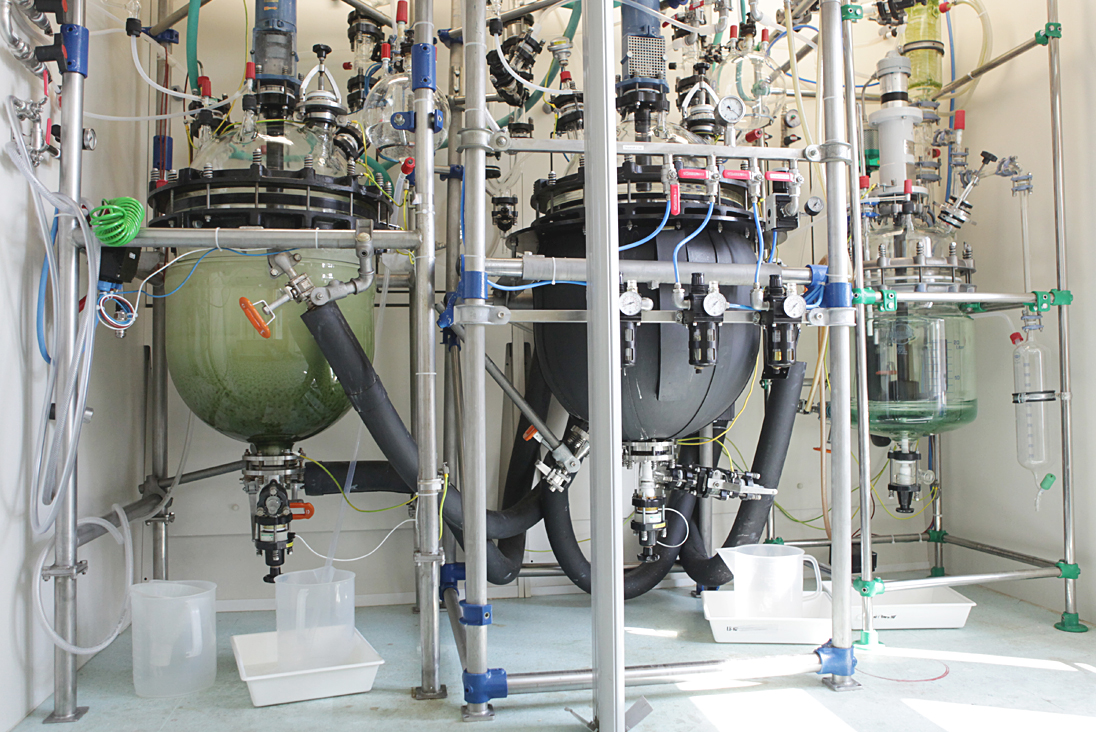

Plant technology

Laborchemie Apolda combines produce dedicated equipment and multi purpose equipment for the maunfacturing of APIs, specialty chemicals and technical chemicals. The production building is separated into cGMP- and non-GMP-areas.

- Glass-lined reactors from 160 L till 3200 L

- Stainless steel reactors from 600 L till 1000 L

- Glass reactors from 30 L till 300 L

- Destillation columns for high vacuum (< 1 mbar)

- Stainless steel centrifuges, Hastelloy pressure filters

- Various dryer

- temperature range from -25 °C till +160 °C

Many years of experience

Chemical reaction types

- Acylation / Alkylation

- Bromination

- Cyclisation

- Chloration with Thionylchloride

- Ethersynthesis

- Organometallic reactions

- Grignard-reactions

- Suzuki cupplings

- Hydrogenations (< 6 bar)

- NaBH4 reductions

- LiAIH4 reductions

- Ring closure reactions

- Esterfications

- Handling of H2S

- Handling of hazardous chemicals (POCl3, PCl3, TiCl4)

Various possibilities

Chemical name reactions

Nearly all known chemical reactions from A like aldol-reactions to Z like Ziegler-Natta-Reaction can be performed in our production equipment. If you are looking for a partner for special reactions, please do not hesitate to contact us and send an inquiry to sales@laborchemie.de.